|

|

Product Details:

Payment & Shipping Terms:

|

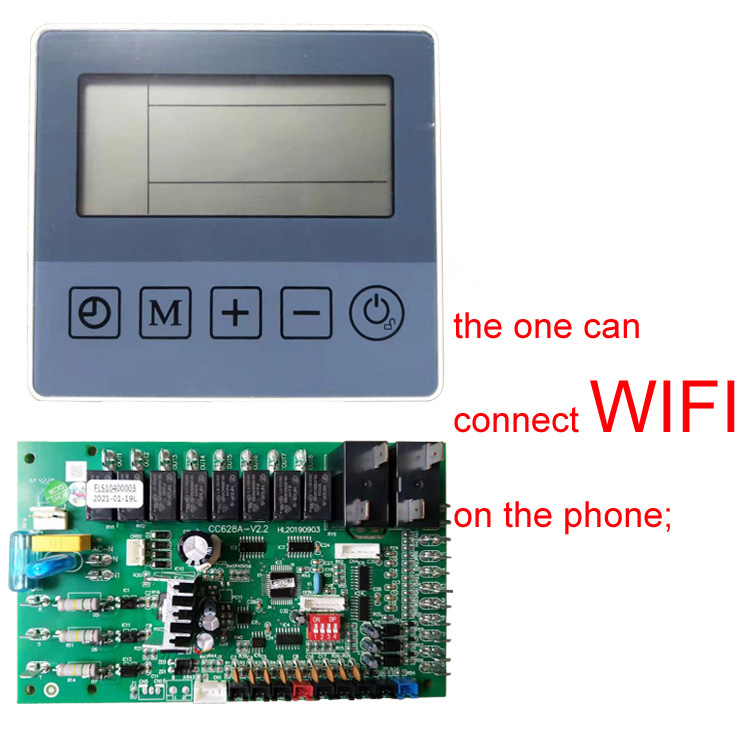

| After-sales Service Provided: | Free spare parts | Power Source: | Electric |

|---|---|---|---|

| Model Number: | FA-08 | Refrigerant: | R410A |

| Heating capacity: | 27kw | Cooling capacity: | 19.6kw |

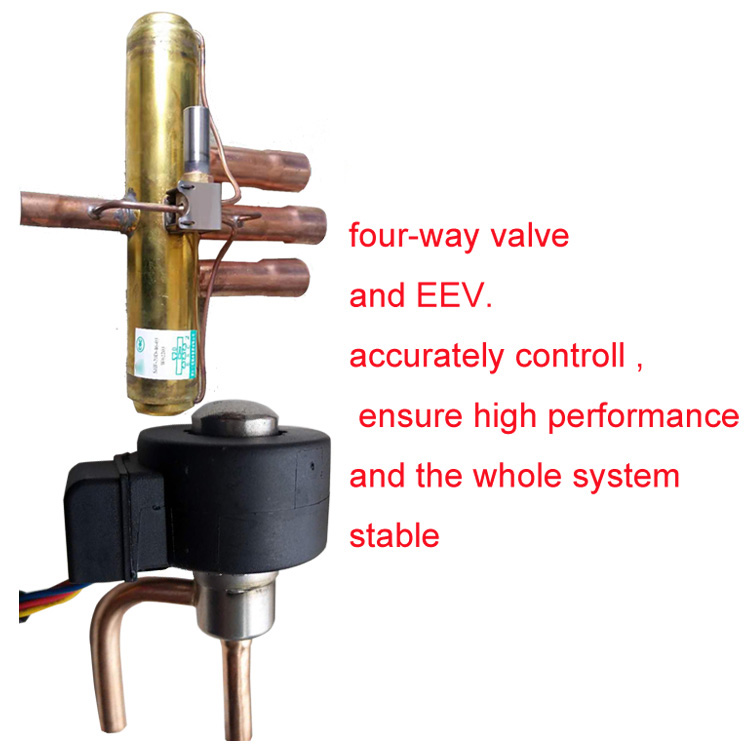

| Expansion Valve: | Sanhua EEV | ||

| High Light: | |||

| Model | unit | FA-20 | ||

| Rated heating capacity | KW | 76 | ||

| BTU | 259386 | |||

| Hot water supply | T/h | 1.93 | ||

| Average heating input power | KW | 16.2 | ||

| Rated heating input current | A | 26.51 | ||

| Max outlet water temp | ℃ | 60℃ | ||

| COP | 4.69 | |||

| Power | V/Hz | 380-415V/50HZ/60HZ | ||

| Nosie | dB(A) | 60 | ||

| Dimension | Width | mm | 1700 | |

| Deepth | mm | 900 | ||

| Height | mm | 1215 | ||

| Unit weight | KG | 520 | ||

| Throttling type | Electronic expansion valves | |||

| Refrigerant | R410A, R32 | |||

| Working air temp range | – 20℃~45℃ | |||

| Compressor | Type | Scroll Copeland,.hitachi,panasonic | ||

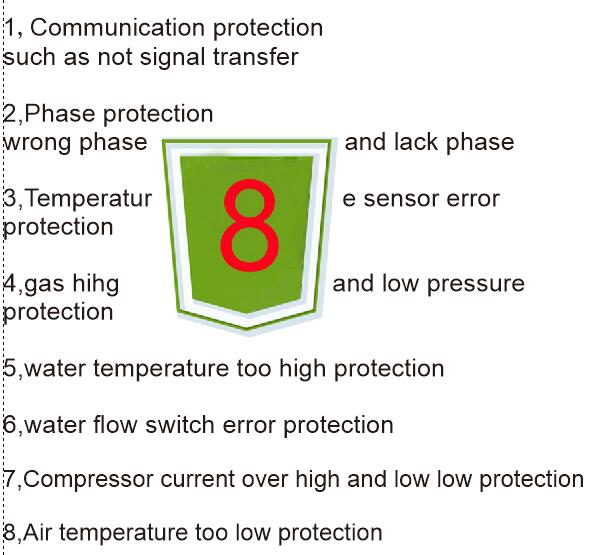

| Security functions | Built-in protection device overheating protection, sequence protection, undervoltage protection, delay protect | |||

| Air source heat exchanger | Type | Finned heat exchange | ||

| Qty | piece | 4 | ||

| Fan type | Axial big twist Angle fan | |||

| Motor power | W | 550*2 | ||

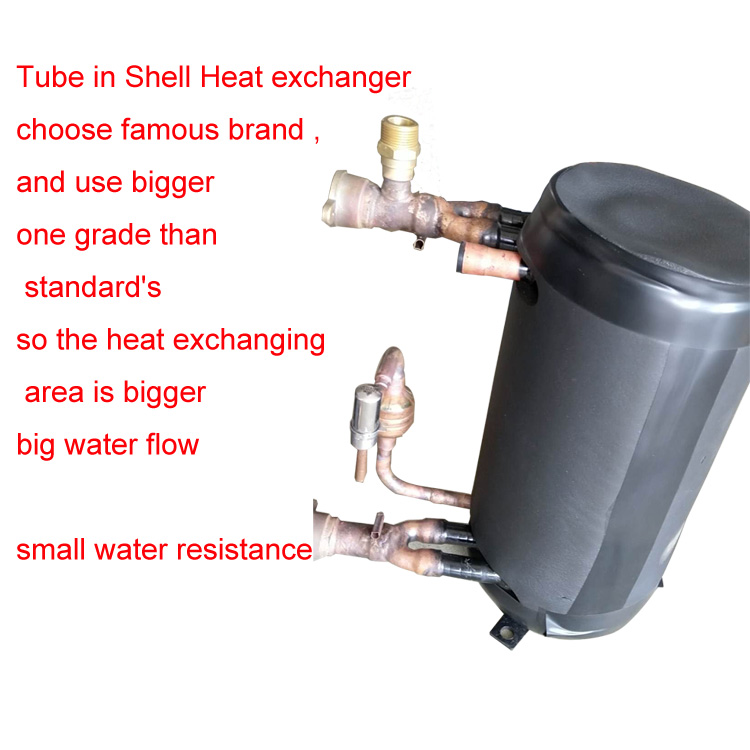

| Hot water side heat exchange | Type | tube in shell heat exchanger OR Shell tube heat exchanger | ||

| Water flow | m3/H | 13.07 | ||

| Water pressure down | kPa | 41 | ||

| Pipe size | Inch | 2 | ||

| Water side max working pressure | kPa | 1000 | ||

| Circulate water pump | No | |||

| water flow switch | Yes | |||

Air SourceHeat Pump hot water heater air to water heat pump heating,cooling FA-08 27KW

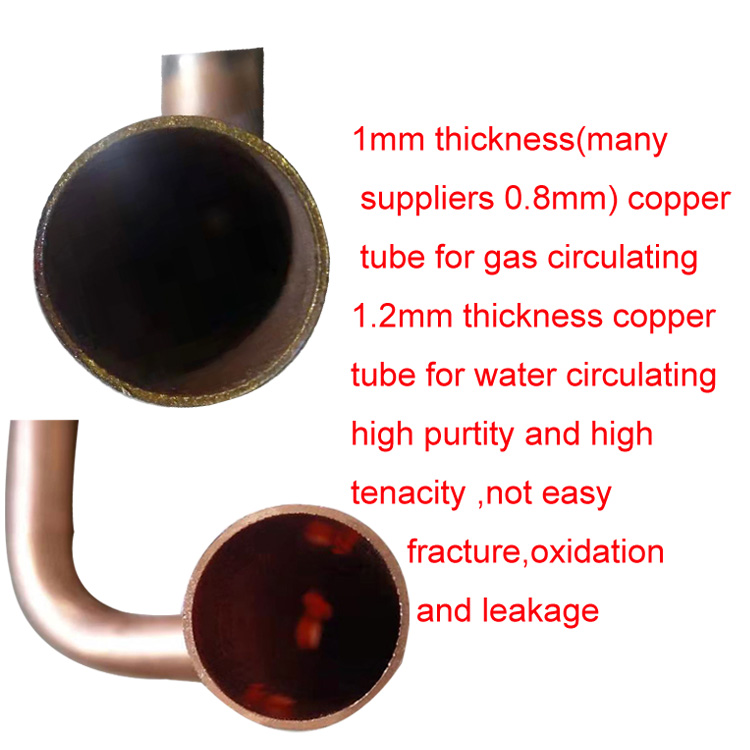

Good welding technique to ensure not eay leaking

Functions

Other function

1,Anti-freeze in winter

2,Timing on/off at fixed time

3,Linkage connect to BMS

4,Automatically and forced defrost function

5,,,,

Our Advantages

1) Base frame and external panels made of galvanized powder coated steel

2) Extremely compact structure and good demountability

3) Reliable compressor with R410A refrigerant

4) Galvanomagnetic reverse valve

5) Intelligent controller and adjustment by quick mind microprocessor with possibility of remote control

6) Water exchanger equipped with high efficiency tube in shell heat exchanger

7) Air exchanger (fins-coil) with hydrophilic coating

8) Automatic defrosting function included

9) Thermostatic heating element for evaporator anti-frosting protection

10) Thermostatic or Electric expansion valve

11) General testing and operational test carried out for every unit before package in the factory

12) Stable water flow switch built-in

protect functions

Our factory

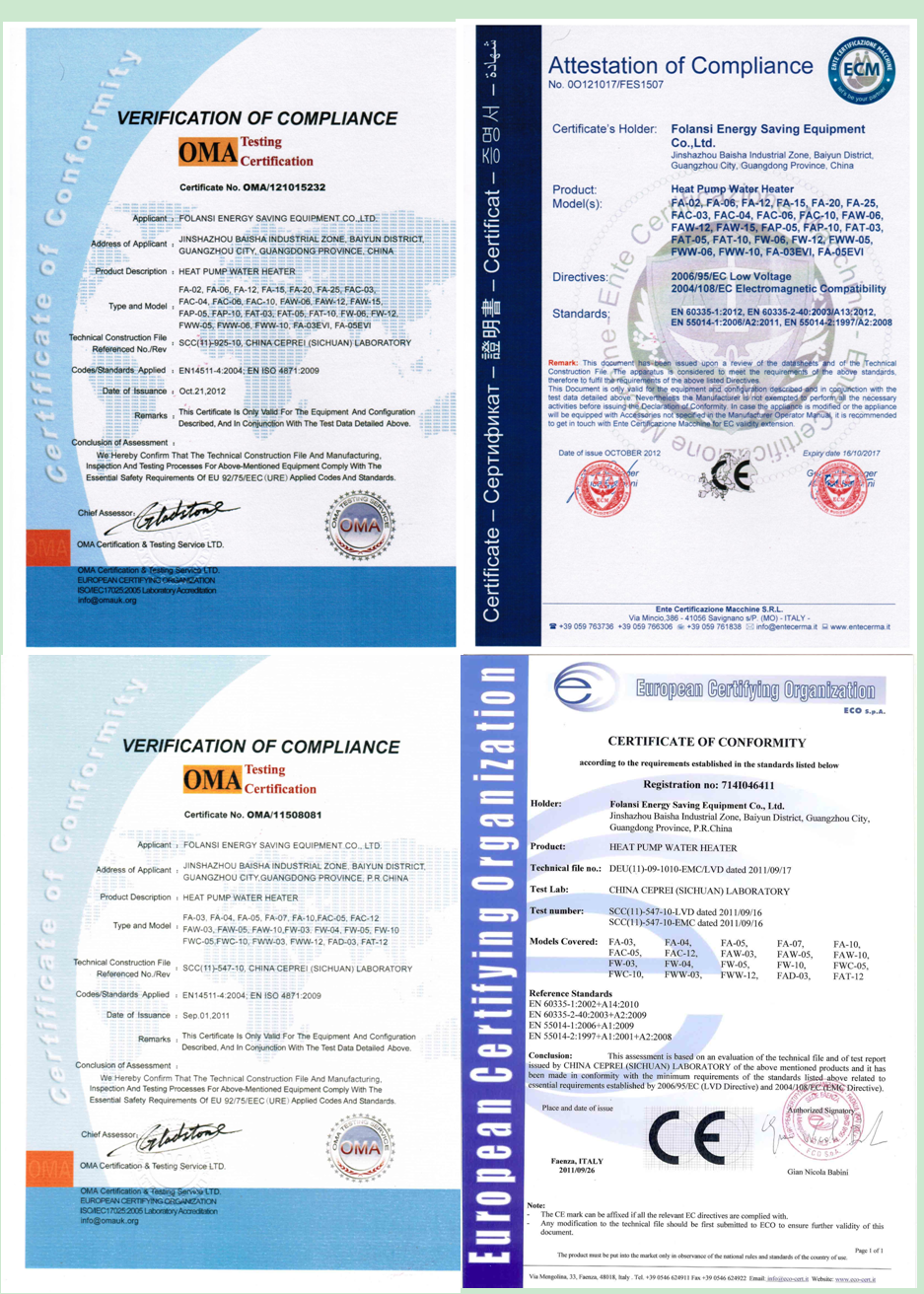

Certifications

we have CE,EN14511,ERP energy efficiency certificate